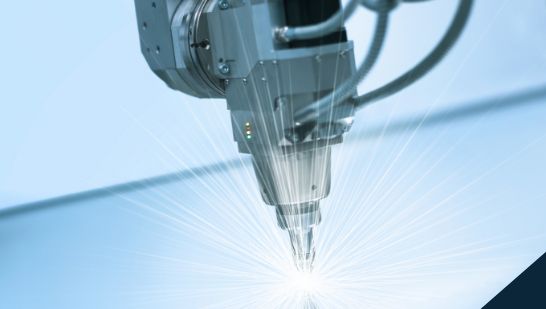

Small and medium series laser welding

Microweld's combination of the latest CNC equipment with a mastery of new generation micro laser welding techniques means we can manage small to medium series of geometrical complex components.

Microweld's combination of the latest CNC equipment with a mastery of new generation micro laser welding techniques means we can manage small to medium series of geometrical complex components.

Our engineers and technicians study your requests and devise optimal technical solutions to optimise your part and its associated processes, all the while ensuring your component fully complies with your requirements.

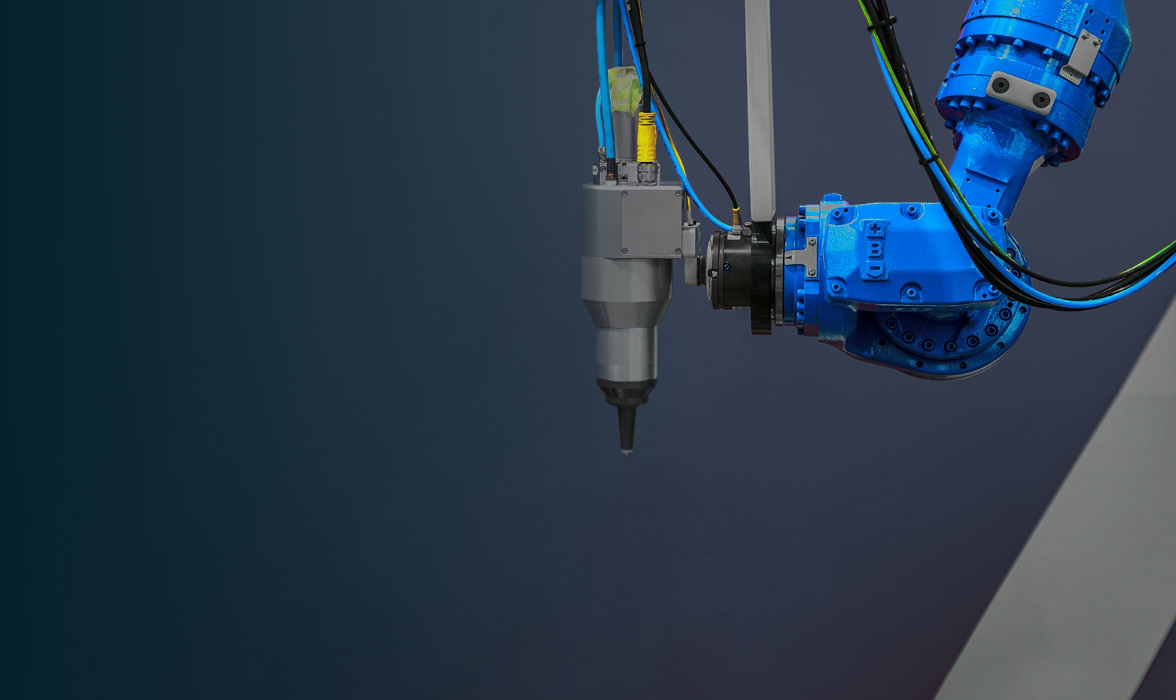

Our new generation CNC equipment is comprehensive and diversified, and enables us to assemble metal (steel, stainless steel, titanium, aluminium, copper) components. Our expertise allows us to provide welding solutions on materials such as cobalt-chrome, kovar, anvar, nitinol, inconel, molybdenum, nickel and its alloys…

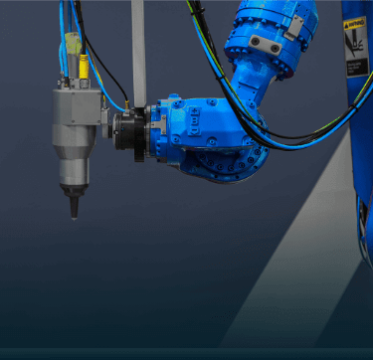

Our mastery of new generation welding techniques, especially robotic laser welding enables us to perform even the most complex welding geometries.

Our company is committed to and recognized for being responsive, providing state-of-the-art technology and advice, while meeting your specifications, quality requirements and production constraints.