Implantable Medical Devices

Microweld offers you the human skills and industrial means to meet the current requirements in the manufacturing of implantable medical devices.

Microweld offers you the human skills and industrial means to meet the current requirements in the manufacturing of implantable medical devices.

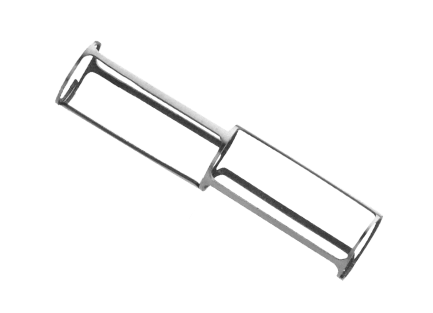

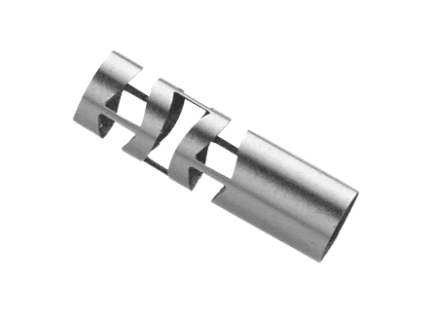

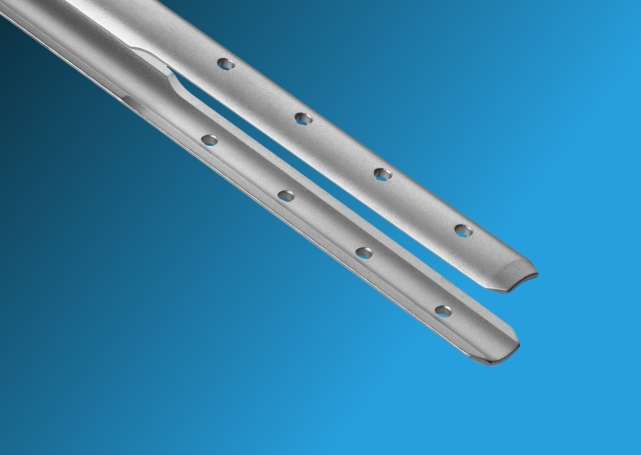

Microweld masters high-precision micro welding and micro cutting techniques, specific to the constraints of the medical industry.

We have the latest laser technologies (continuous laser, pulsed laser, disc, fiber, diode) that adapt to the materials of your products and your complex and miniaturized geometries.

Our system certifications guarantee our customers control over our processes.

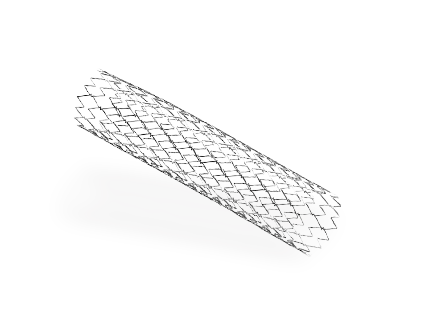

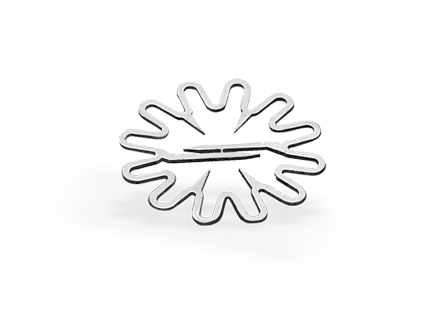

All recent materials from the medical industry are part of our fields of expertise, such as Nitinol (shape memory material used for implants and instruments).

We use all other more common materials such as titanium, tantalum, all stainless steels.

In any case, contact us so that our experts can respond to you for any request for subcontracting on more specific materials.

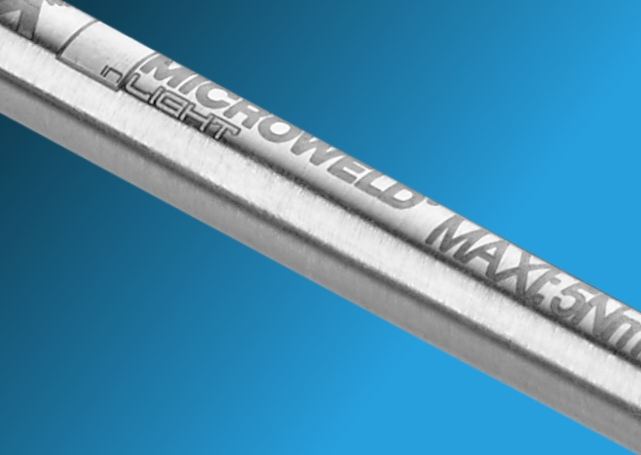

Beyond subcontracting welding or cutting, we have equipment capable of marking and finishing your products’ surface (engraving from while ensuring the mechanical performance of the parts).

Logo, alphanumeric text, barcode, datamatrix, QR code, high strength and high contrast using the latest generation laser techniques.

Our system certification guarantees your product quality for each of your batches (delay, mechanical performance, dimensional, traceability, appearance and cleanliness, documentation, packaging).

Engineers and technicians dedicated to each of your projects, from small to large series

Throughout the development process, a dedicated team manages your projects on all levels: commercial, technical, quality and logistics.

We carry out the QP qualifications during the first pre-series in accordance with your qualification protocols.

All our services are tailor-made, whether in terms of technical, quality and logistics. We ensure that our high-precision services meet all the expectations of our customers.