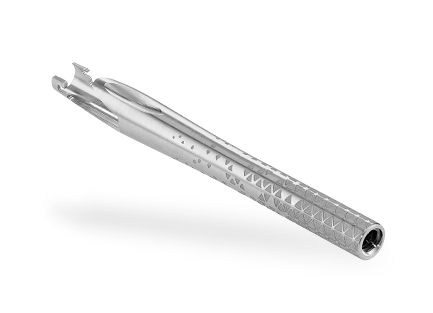

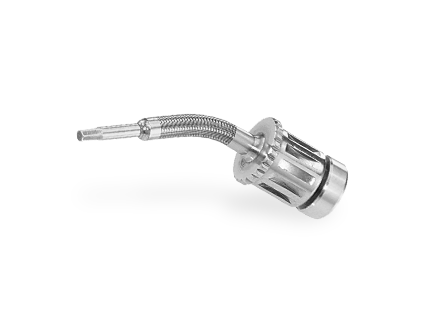

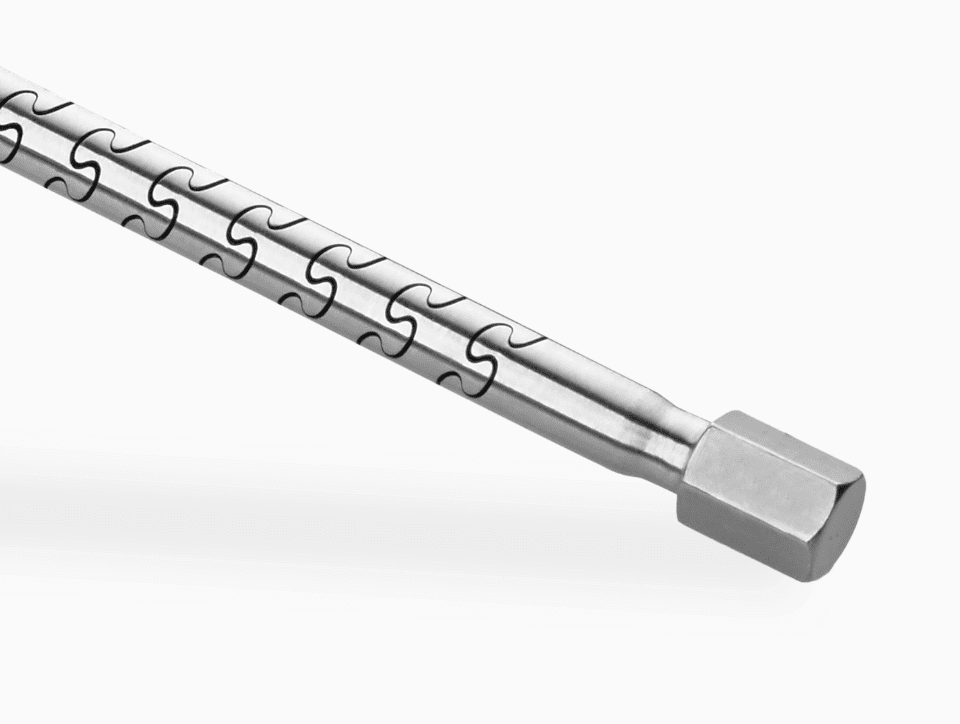

Medical Instruments and Ancillaries

Microweld uses the latest laser techniques to manufacture a variety of medical instruments and ancillary products.

Microweld uses the latest laser techniques to manufacture a variety of medical instruments and ancillary products.

Our expertise in the production of medical instruments and ancillary products ranges from simple components to complex connected assemblies, whether reusable or single-use. This includes but is not limited to:

With its wide range of processes (microwelding, marking, cutting, assembly, brushing, bead blasting, shaving, tribofinishing, US cleaning, passivation), MICROWELD delivers ready-to-ship instruments that fully meet your requirements and compliance constraints.

We provide the latest micro welding technologies: Laser, Micro TIG or TIG, with or without metal filler.

With our finishing workshop, we guarantee our customers a perfect finish including post-treatments such as cleaning and passivation (nitric or citric).

Microweld is a force of proposal from the start of the project to advise on the best technical paths to take.

In all cases, consult us so that our experts can discuss with your teams and meet your expectations in order to propose the best material combinations.

Our system certification guarantees your product quality for each of your batches (delay, mechanical performance, dimensional, traceability, appearance and cleanliness, documentation, packaging).

Our product team will work hand-in-hand with you to proposae the best materials , geometries and processes to adopt to gain the opitimum results.

We implement all the necessary and sufficient controls to guarantee your requirements: appearance, mechanical test, dimensional measurements and controls, metallographic cut, material health by 3D X-ray tomography.

All our services are tailor-made, whether in terms of technical, quality and logistics. We ensure that our high-precision services meet all the expectations of our customers.