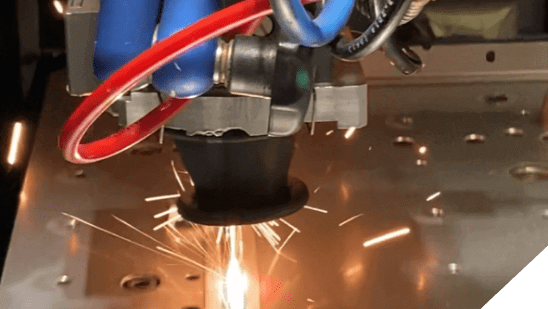

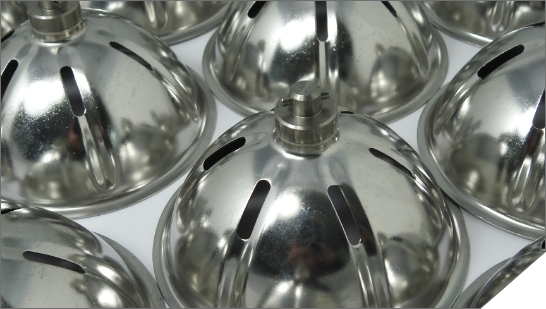

Large series laser welding

Microweld has substantial industrial and technical capacity and is therefore able to position itself in major markets that require large series micro welding production while maintaining the highest quality.

Microweld has substantial industrial and technical capacity and is therefore able to position itself in major markets that require large series micro welding production while maintaining the highest quality.

According to your specifications, or at the end of the feasibility study, we develop specific micro laser welding solutions that are fully adapted to your requirements. The dedicated team in our Project Department is in a position to manage new markets efficiently.

Microweld sets up and coordinates the adequate technical and human means to best implement your projects. Our teams work in two 8-hour shifts comprising dedicated project adjusters and qualified operators.

Microweld has substantial industrial capacity and is therefore able to position itself in major markets via production and technical capacity combined with top-quality.

Microweld can take charge of supplementary activities: